Liquid paint coating for electronic plastics.

Because the perfect dosing and mixing performances will condition the life time of the coated parts, we have designed the most precise and efficiently mixing machines with our CYCLOMIX range.

High Power of Atomization (HPA) range of sprayers will allow you to get the perfect finishing quality to meet the OEM requirements and get a good color match between parts assembled on the final product.

High gloss with uniform thickness, low paint losses with an efficient process, and optional 2K mixing in the sprayer’s head is also a perfect solution that we offer in the various process for plastic objects.

When plastic parts need a high finishing quality we can provide premium application equipment & systems.

High Power Atomization (HPA) is our best airspray technology & delivers the highest finishing quality among all standards. It is recommended when finishing quality with metallic effects is the priority.

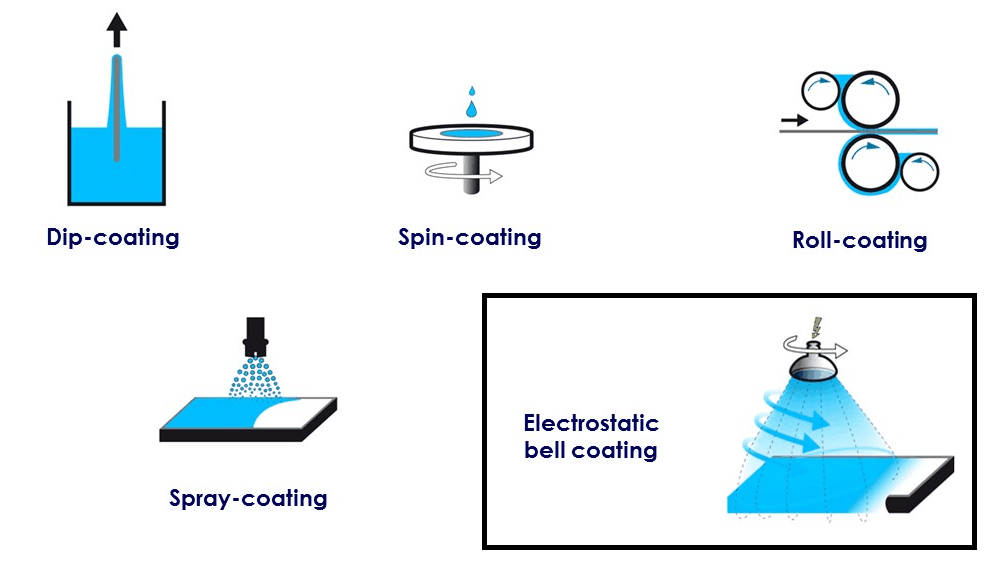

Bell Spray technology is used for clear coat high gloss applications & when uniformity of the film thickness is required.

Electrostatic charge is used for HPA & standard bell spray applications. For optimal results, conductive primer layers are sprayed before the electrostatic application allowing high transfer efficiency & material savings.

Replacing conventional airspray guns in a factory with electrostatic bell spray not only saves paint and dramatically increases production output, it also has a quick payback on the upgrade.

Occasionally this will allow you to keep an existing line and still get the required increase in production without investing in a new line.

Sol-gel glass coating.

SOLGEL definition:

In materials science, the sol-gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon and titanium. The process involves conversion of monomers into a colloidal solution (sol) that acts as the precursor for an integrated network (or gel) of either discrete particles or network polymers. Typical precursors are metal alkoxides.

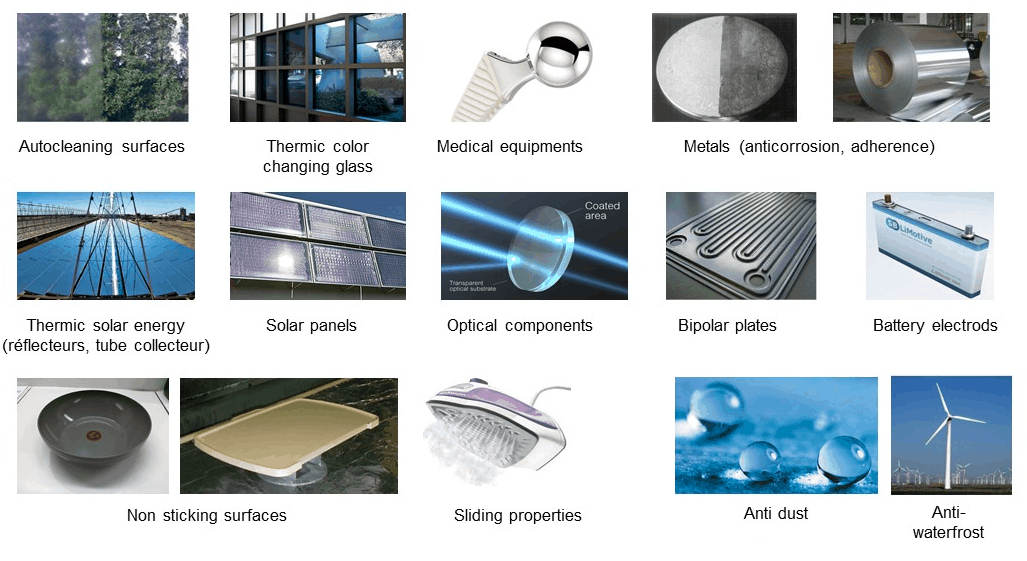

Applications:

The applications for sol gel-derived products are numerous. For example, scientists have used it to produce the world’s lightest materials and also some of its toughest ceramics. One of the largest application areas is thin films, which can be produced on a piece of substrate by spin coating or dip coating. Protective and decorative coatings, and electro-optic components can be applied to glass, metal and other types of substrates with these methods. Cast into a mold, and with further drying and heat-treatment, dense ceramic or glass articles with novel properties can be formed that cannot be created by any other method. Other coating methods include spraying, electrophoresis, inkjet printing or roll coating.

Glass bonding in architectural application or transportation requires strong adhesion, lasting characteristics (up to 30 years), and the highest level of safety. A controlled process with high performance materials are needed.

2K dosing, mixing & dispensing machines are necessary to ensure the right performances of the material.

We have mechanical machines (P85) or electrical machines (BOOSTHOR) to meet your material, final application & process needs.

For example, VEC system – 2K silicon glue 10:1 ratio is using our mechanical machine P85 successfully for the most demanding users.

Allows a robust process with easy maintenance & long-lasting performance.

Protective coating for windmill parts & components.

Finishing 1K or 2K paint, solvent, or water-based (primer, top coat, clear coat).

Single or plural component paint solutions for towers.

1K or 2K component gel coat & top coat, solvent- or water-based applications.

Protection, sealing & finishing for steel drums

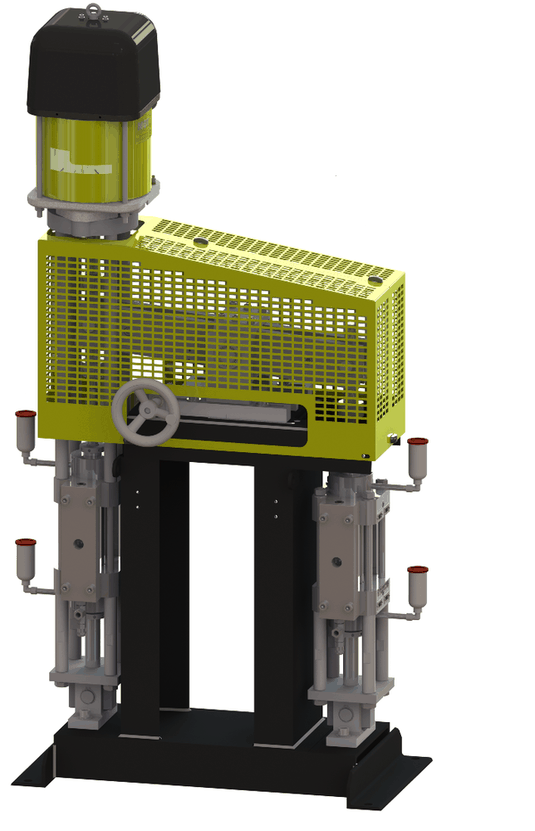

Outperforming spraying solution for tight head drum coating horizontal line with a production capacity of 450 drums/hour.

Outperforming spraying solution for tight head drum coating vertical line with a production capacity of 600 drums/hour.

Spraying solution up to 3 color changes – drum using stripping shield.

Drum cover /lid finishing with special spraying up to 15 % saving with a production capacity of 800 lid/hour

Interior drum finishing

steel drum retrofit tight head or open top

Anti-corrosion & protective coating for piping structures.

Innovative process with Inobell powder bell solution:

Automatic airless® process: