High transfer efficiency release agent coating for molding processes.

Release/demolding agent on a grease wax base will be used for casting & molding applications. With more complex materials, cost can be an issue & high transfer efficiency may be required. Alternatively, a constant & uniform film thickness may also be requested.

Electrostatic bell application is a must for high transfer efficiency spray in the industrial processes. NANOBELL from SAMES KREMLIN can produce the job while saving cost & cycle time.

To ensure the perfect release of the part from the mold after operation, the demolding agent must be sprayed on the complete surface with a specific thickness. Electrostatic bell spray can reach these requirements.

Automatic/robotic process for the demolding agent will prevent operators from exposure to demolding agent fumes. High efficiency process will also limit the fumes & overspray.

Liquid & powder protective coating for gas bottles & tanks.

Treated to be anti-corrosive, gas cylinders are sprayed by manual or automatic powder systems to comply with the highest environmental conditions and highest productivity.

For this market, powder coating is only used for domestic gas bottles.

Gas cylinders are often “color coded” requiring fast multi-color spraying systems in automatic modes.

Liquid finishing application is often used for gas bottle maintenance.

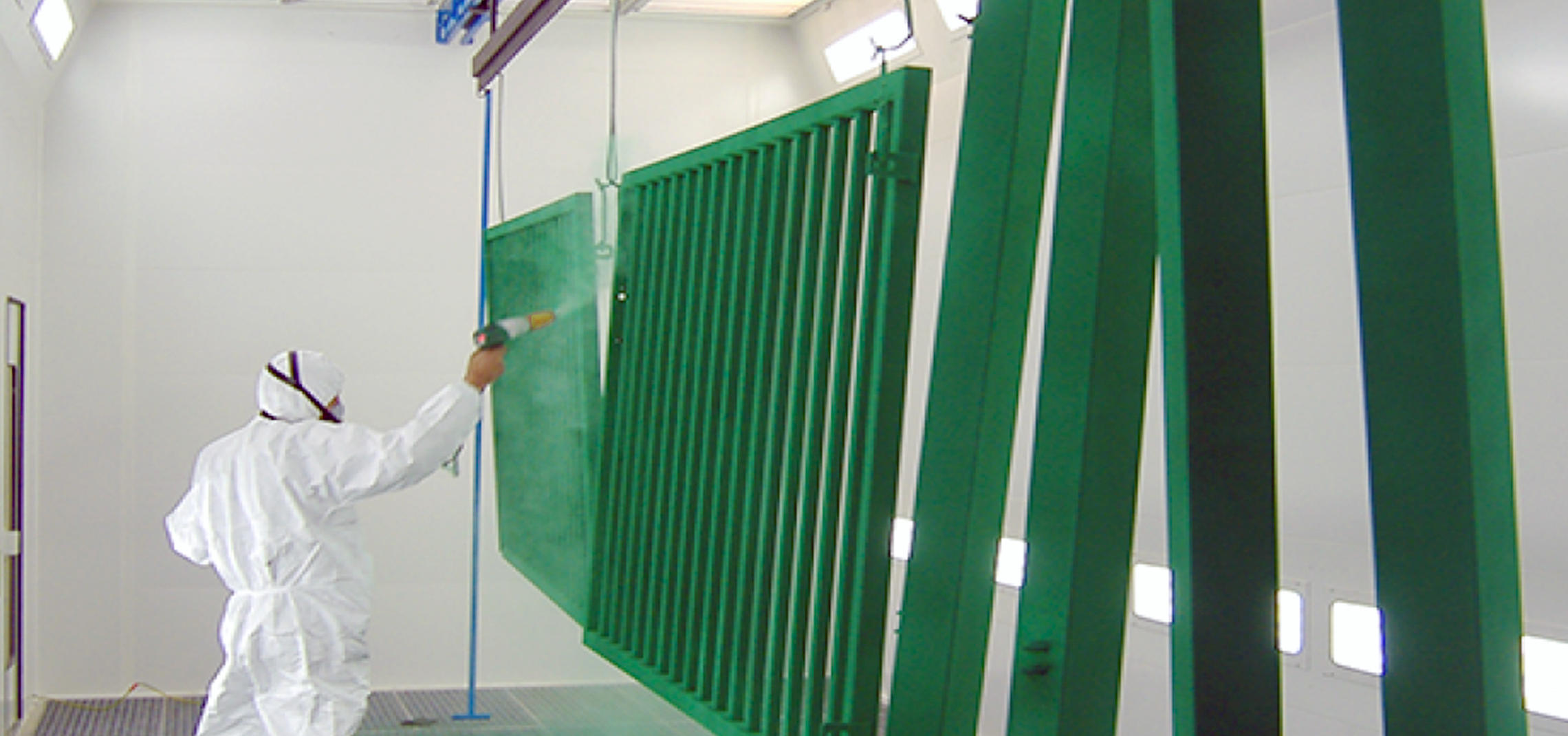

Subcontractors of the surface treatment and the coating process for the general industry.

Job coating is a very demanding task, as many type of paints and colors have to be managed, with a wide variety of parts. The installations must be very flexible, but the performances have to be always at the top as painting result is the main function that the customer pays for.

Job coaters are under the pressure of cost per unit reduction, from industrial OEM who have outsourced the protective and decoration functions to an expert. therefore, they need to use very efficient solutions.

Protective coating for sea containers.

Protective coating manual or automatic airless® or electrostatic spraying systems:

Spraying of high nickel zinc 2K primer

Top coat on flat or corrugated surfaces

Interior sealing & Airless® spraying.

Protective underbody blackout Airless® spraying.

Protective & finishing coating for yacht & sea vessels.

Windshield bonding.

Window bonding & sealing.

Bridge & hull bonding.

Roof bonding & sealing.

Tech bridge sealing.

Composite parts manufacturing (infusion, coating) and assembly with bonding and sealing.