This compact Airmix® paint pump is the ideal partner for your Airmix® spray guns providing exceptional finish quality & high transfer efficiency.

The 30C25 Airmix® paint pump delivers excellent performance and outstanding benefits because of our proven pumping technology. The 30C25 compact Airmix® paint pump is recommended to handle all types of materials ranging from low to medium viscosity. It comes with an optimized volume fluid section for fast color changes with minimal material loss.

The 30C25 Airmix® paint pump packages are available in wall-mount versions with stand mounting as an option. Packages are available with (1) Xcite™ 200 bar Airmix® manual spray gun and 7.5 m (25ft) air and fluid hoses. A wide variety of options are available to meet all customer requirements.

The 10C18 AIRMIX® professional paint sprayer is only available as a complete spraying package. It ensures constant and pulse free delivery for superior finish.

Recommended for small industries to benefit of both Airmix® spray technology advantages and simple and performing Sames Kremlin pump range. Economic solution to handle low viscosity materials (up to 3000 cps) with a very low motor air consumption and a low volume fluid section for fast color changes with a minimum of product loss

The 10C18 Airmix® pump packages are available in either stand or wall-mounted versions (cart mounting as an option). Packages are available with one Xcite ™ 120 bar manual Airmix® paint sprayer equipped with or without an 06.094 tip size and 7.5m (25ft) fluid and air hoses. A large variety of accessories and tools is available for any customer needs.

All our equipment are designed for any industrial professional application projects. The 10C18 painting equipment is an essential and unique offer to benefit of SAMES KREMLIN premium quality equipment and all the Airmix® benefits. Choosing this equipment will really put you in a pole position for quality spraying with a minimum investment for big paint savings, reduced paint booth contamination, cleaner environment and pros operator comfort.

This full package is the ideal choice if your ladders of priorities is to get an efficient equipment for your paint job ready to connect to your paint buckets or tray (as in the diy market). It is ideal to meet any type of production job in every market (metal, wood and furniture items, plastic,, …) and for every part frames.

Our equipment features stainless steel construction to dispense solvent or wayer-based fluid products such as coatings (top coats, primers, varnishes, stains ….) for any kind of production applications rates with a great transfer efficiency. The minimum overspray will minimize masking operations,

Our 10C18 painting equipment supplies paint to our Xcite Airmix® spray gun for a perfect atomization, ideal fan pattern size and meets any type of production need in every market (metal, wood, plastic, railways,, …).

Our pumps packings are designed for a long shelf life. They are designed for operator safety, skin and as an extension cloths care (closed construction)

We also supply all pump accessories and tools to apply paint in the most efficient way. All you need to do is submit your need to your local distributor stores, which reviews your application to determine the best tip size. Our range – dedicated to the industrial finishing production industry includes also other spray pumps kits fitted with spray guns and hoses if ypur needs may evolve (need to paint larger parts, ceilings ….).

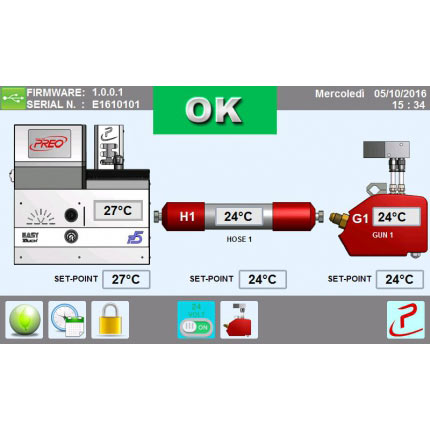

The EASY TOUCH systems are equipped with a new microprocessor with 7″ LCD Touch Screen colour display, through which, with a single graphic interface showing all sections of the system (tank, manifold, hoses and guns). The operator is supported in everyday activities like managing and setting temperatures, pump control, setting machine parameters and glue sections, and integration and communication with any external units, allowing for immediate use of the system even by nonspecialized personnel, without any problems involving codes or foreign languages to be interpreted.

The following are some of the main functions of the new user interface: sequential channel heating, machine ready and pump start signals, absolute maximum temperature protection system, Economy Dual Mode, Weekly Program with Daily ECO function, colour status button with real time diagnostics and Screen Saver function, hose-gun coupling thermal regulation deactivation, LOG file for system register, Life Hours/Work Hours/Pump Cycles counter, machine parameters and Firmware updates uploaded and downloaded through a USB port, customizable system section and glue program names, and parameter Copy/Paste function.

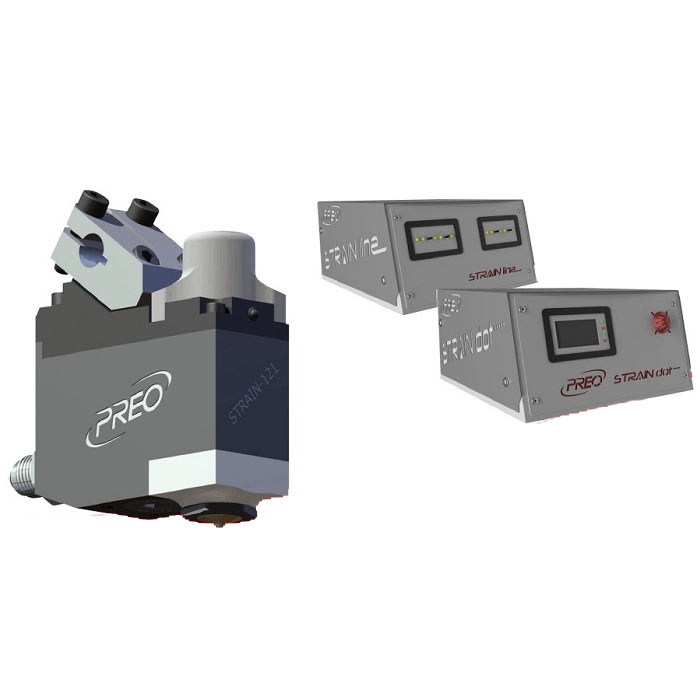

STRAIN 121 electromagnetic guns are the most sophisticated, innovative, and technologically advanced on the world market today. They stand out from their competitors due to their speed, compactness, precision, repeatability in supply, ease and speed of installation, as well as being completely noise free. They are particularly suitable for applying and supplying micro-points of thermal adhesives even at very high speeds of up to 5,000 Cps. They can reach a cycle speed of less than 1 millisecond and an overall lifecycle of tens of millions of strokes.

ELECTRICAL CONNECTIONS

The electrical kit is easy, quick, and safe to extract.

MICRO-REGULATION SYSTEM

A precise micro-regulation system guarantees simple, perfect formation of micro-points of glue, even at very high speeds.

HIGH SPEED ACTUATOR

This makes it possible to supply a glue point in less than 1 millisecond, with maximum repeatability.

ENERGY SAVING

An innovative energy saving system makes it possible to recover up to 50% of the electricity used for the gun to operate.

INTEGRATED MODULE

All the gun’s components are assembled inside the casing, which makes maintenance easier and reduces the quantity of spare parts required.

GUN CASING

The material used to make the guncasing is “Ergal”, which signifi cantly improves performance in terms of strength to resist mechanical forces. A hard oxide coating makes cleaning and maintaining the gun quicker and simpler.

GLUE FILTER

Easy to access and replace, it ensures a better distribution of the adhesive preventing the nozzle clogging due to the presence of impurities in the adhesive. It is integrated and easy to change.

“REDUCED-CAVITY” NOZZLE

The nozzle is made of special high strength material and guarantees maximum repeatability, exceptional reliability, and very high precision, as well as uniformity of the micro-points of glue deposited.

STRAIN DRIVER

The STRAIN DRIVER 121 digital control unit runs up to 2 guns fully independently for all functions and allows repeatability that far outstrips normal applications, thanks to its innovative electronics.

CONNECTIONS

A terminal board with a rapid coupling connector on the back of the unit is used to connect all the Input and/or Output signals and the photocells required for the system to operate properly.

GRAPHIC DISPLAY

It displays graphically the sections and the programmable parameters allowing a very easy way to program the guns even by non-specialist personnel, eliminating problems generated by codes and foreign languages.

PROGRAMMING SELECTOR

An innovative selector with built-in button controls the programming method of all the operating parameters: every time the knob is pressed, another parameter appears, which is increased or decreased simply by turning the knob.

LIGHT INDICATORS

4 LEDs show the system status and any alarms or faults that arise while the unit is operating.

SAFETY KEY

Once the control unit has been programmed, the data entered can be protected by using the safety key located on the front panel.

The handguns series Shark are the ideal solution for manually dispensing hot melt adhesives, waxes, sealants and many other similar thermoplastic materials. Ergonomic, reduced weight and functioning, they can be used for applications like packaging, hand-case sealing, sampling, palletizing and products’ assembly. The Shark handguns fit with any PREO gluing system with piston or gear pumps and are available in two different versions, bead or spray. The small amount of mechanical components and seals reduce your guns’ cleaning and maintenance costs. The heat distribution in the gun is realized with high reliable rugged built-in cartridge heaters and is controlled accurately through PT100 sensor, which allow a perfect temperature adjustment. A wide range of nozzles and thermo-heated hoses of different lengths are available to complete the application

360° ROTATING CONNECTION

Complete flexible usage thanks to the 360° rotating connection and to the lack of any external electro-pneumatic wires, which allow to work with extreme freedom, without any risk of damaging due to the hose twisting.

INSULATION COVER

Electric components and glue flow directions are placed inside the gun body and not inside the handle, in order to avoid overheating of the handle itself. The heat distribution in the gun is uniform and the insulating sidings, realized with high-reliable materials, allow the operator to work without any risk of contact with the adhesive.

MODULE WITH INTERCHANGEABLE CARTRIDGE

More than 70% reduction of the maintenance time, thanks to the module equipped with interchangeable cartridge system.

DISTRIBUTION LEVER

BEAD version: lever with progressive drive and manual lock for preventing any unintentional adhesive release.

SPRAY version: lever with progressive drive and manual lock for preventing any unintentional adhesive release.

NOZZLES

BEAD version: the Shark handguns are supplied with bead nozzles with a minimum diameter of 0,30 mm and a maximum diameter of 3,30 mm.

SPRAY version: the Shark handguns are supplied with spray nozzles with a minimum diameter of 0,30 mm and a maximum diameter of 2,00 mm.