SPRAY and SPYRO gun series are mainly employed for gluing wide surfaces where a low glue weight is required. Main features of the SPRAY and SPYRO guns are: AMX 45 module with double interchangeable gasket cartridge, Zero-Cavity self-cleaning nozzle with nebulisation air cap, air heating block, possibility of a second solenoid valve for separate nebulisation air control, protective non-stick casing coating, integrated glue filter which is removable without disassembling the hose. This wide, complete range of different models makes it possible for even most demanding Customer to find the best solutions for any gluing needs. The wide range of models provides also the most demanding customer with the ideal solutions for each gluing problem

In addition to standard solenoid valves, Preo has developed a new model that is ranked at the top of the market offer. Depending on the applications required, this valve can deliver the highest level solution for tasks that require low energy consumption, high-speed application and small size and weight.

Removing the electrical kit is easy, simple and safe.

The casing is built in “Ergal”, an aluminium alloy that considerably improves the product’s resistance to mechanical stress. The hard oxide cover makes gun cleaning and maintenance quick and easy.

The gun is heated with highly reliable heating coils controlled by extremely precise sensors.

Inside the gun casing is assembled a new heating block which keeps a constant temperature of the air used for the product spraying, thus ensuring precise and reliable results.

All guns are equipped with a new AMX 45 Series module that ensures precise, regulated glue application. This level of performance was possible only because of the special attention dedicated during the design and construction phases. The most important aspect of the AMX 45 module is its innovative gasket system with the double interchangeable cartridge, which guarantees a perfect seal at high pressures

and temperatures in addition to simple, inexpensive, and long-lasting maintenance.

This guarantees better distribution of the glue and prevents nozzles from clogging due to the presence of impurities in the glue. It’s integrated into the casing, and is easily accessible and can be quickly replaced without disassembling the hose.

The guns are available in 2 different series depending on the provided nozzle: the Spray version is used for an even spraying of the product, while the Spyro version allows you to obtain spiral-shaped glue strips. The gun are supplied with stainless steel Zero-Cavity self-cleaning nozzles, available with a minimum diameter of 0.30 mm to a maximum of 1.2 mm. Zero-Cavity is the term used for the cut-off that directly closes the nozzle hole, eliminating any possible impurities and guaranteeing the constant cleanliness of the nozzle. This guarantees that the system always works properly. The wide range of nozzles includes a number of configurations and special designs, based on the Customer’s needs.

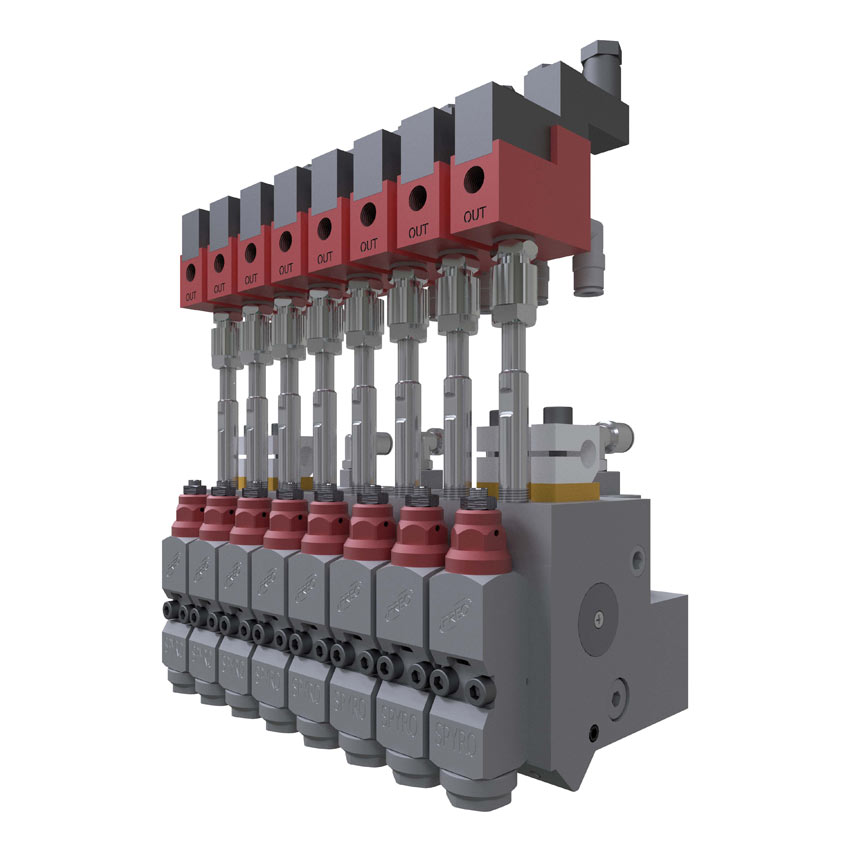

The REVOLUTION Gun Series equipped with modules with different types of centre diameters, provide the best solution for each gluing problem and thanks to their small size and versatility can replace the common standard multi-module guns with fixed centre distances. The Revolution’s main features are: speeds up to 6.000 cycles/minute, AMX45 module with double interchangeable gasket cartridge, Zero Cavity self-cleaning nozzle, protective non-stick casing coating, integrated glue filter which is removable without disassembling the hose. A wide and complete range of models makes it possible for even most demanding Customers to find the best solutions for any gluing need.

SOLENOID VALVES

In addition to standard solenoid valves, Preo has developed a new model that is ranked at the top of the market offer. Depending on the applications required, this valve can deliver the highest level solution for tasks that require low energy consumption, high-speed application and small size and weight.

GUN CASING

The casing is built in “Ergal”, an aluminium alloy that considerably improves the product’s resistance to mechanical stress. The hard oxide cover makes gun cleaning and maintenance quick and easy.

ELECTRICAL CONNECTIONS

Removing the electrical kit is easy, simple and safe.

THERMAL-HEATING

The gun is heated with highly reliable heating coils controlled by extremely precise sensors.

AMX 45 MODULE

All guns are equipped with a new AMX 45 Series module that ensures precise, regulated glue application. This level of performance was possible only because of the special attention dedicated during the design and construction phases. The most important aspect of the AMX 45 module is its innovative gasket system with the double interchangeable cartridge, which guarantees a perfect seal at high pressures and temperatures in addition to simple, inexpensive, and long-lasting maintenance.

MODULES WITH DIFFERENT CENTRE DIAMETERS

These guns main feature is the possibility to modify the centre diameter through the simple modules rotation (directly on line and with the gun in temperature); this allows to fulfil many different applications using one only gun. The advantage consists in a high flexibility with a consequent time saving in maintenance, spare parts and line stop.

NOZZLE

The gun is supplied with stainless steel Zero-Cavity selfcleaning nozzles, available with a minimum diameter of 0.25 mm to a maximum of 1.2 mm. Zero-Cavity is the term used for the cut-off that directly closes the nozzle hole, eliminating any possible impurities and guaranteeing the constant cleanliness of the nozzle and a properly working system. The wide range of nozzles includes a number of configurations and special designs, based on the Customer’s needs. Important technical features are: highest level of resistance to wear and tear, thermal conductivity and construction geometry ensuring same reliability as the traditional Zero Cavity nozzles also if using multi-vein nozzles.

GLUE FILTER

This guarantees better distribution of the glue and prevents nozzles from clogging due to the presence of impurities in the glue. The filter is integrated into the casing, and is easily accessible and can be quickly replaced without disassembling the hose.

NEW LIFE series glue guns are built with standard or high-temperature configurations, with one or more modules with different types of centre diameters and nozzles, and with one or more solenoid valves, in order to satisfy the widest range of different requirements. NEW LIFE’s main features are: speeds up to 6.000 cycles/minute, AMX 45 module with double interchangeable gasket cartridge, Zero-Cavity self-cleaning nozzle, protective non-stick casing coating, integrated glue filter which is removable without disassembling the hose. This wide, complete range of different models makes it possible for even most demanding Customer to find the best solutions for any gluing needs.

SOLENOID VALVES

In addition to standard solenoid valves, Preo has developed a new model that is ranked at the top of the market offer. Depending on the applications required, this valve can deliver the highest level solution for tasks that require low energy consumption, high-speed application and small size and weight.

GUN CASING

The casing is built in “Ergal”, an aluminium alloy that considerably improves the product’s resistance to mechanical stress. The hard oxide cover makes gun cleaning and maintenance quick and easy.

ELECTRICAL CONNECTIONS

Removing the electrical kit is easy, simple and safe.

AMX 45 MODULE

All guns are equipped with a new AMX 45 Series module that ensures precise, regulated glue application. This level of performance was possible only because of the special attention dedicated during the design and construction phases. The most important aspect of the AMX 45 module is its innovative gasket system with the double interchangeable cartridge, which guarantees a perfect seal at high pressures and temperatures in addition to simple, inexpensive, and long-lasting maintenance.

THERMAL-HEATING

The gun is heated with highly reliable heating coils controlled by extremely precise sensors.

NOZZLE

The gun is supplied with stainless steel Zero-Cavity selfcleaning nozzles, available with a minimum diameter of 0.25 mm to a maximum of 1.2 mm. Zero-Cavity is the term used for the cut-off that directly closes the nozzle hole, eliminating any possible impurities and guaranteeing the constant cleanliness of the nozzle. This guarantees that the system always works properly. The wide range of nozzles includes a number of configurations and special designs, based on the Customer’s needs. Preo nozzles stand apart from the competition due to their basic technical features, which can be summarized as follows. First: the nozzles are made of durable materials with the highest level of resistance to wear and tear. Second: their thermal conductivity is much greater than the traditional steel, with the advantage of quick heat transmission, at least 8 times higher than normal. Third: concerns the construction geometry, due the fact that multiway

nozzles ensure the same reliability as the traditional Zero Cavity nozzles.

GLUE FILTER

This guarantees better distribution of the glue and prevents nozzles from clogging due to the presence of impurities in the glue. The filter is integrated into the casing, and is easily accessible and can be quickly replaced without disassembling the hose.

The new guns DOUBLE E series, with isolation cover integrated, are available in a wide and complete scale of models to permit the most demanding Costumer to find every time the most suitable solution to each gluing issue. Designed for the distribution of thermoplastic adhesive with high and medium viscosity, they are realized with one or more modules configuration, different center-distances and nozzles and with one or more solenoid valve. The main characteristics of DOUBLE E series are: compact design and reduced dimension perfect for installations in narrow spaces, modular elements, speed up to 8.000 cycles/minute, high reliability with a service life of more than 50 millions cycles, module double effect AMX-45 AOAC (with double interchangeable cartridge), Zero-Cavity self-cleaning nozzle, isolation cover in hard plastic and non-stick protective coating on gun’s case with integrated glue filter removable without disassembling the hose.

SOLENOID VALVES

A large choice of solenoid valves is available, both standard and special expressly developed for guns Double E. Depending on the required applications, these valves can deliver the highest level solution for tasks that require low energy consumption, high-speed application, small size and weight.

INSULATION COVER

Produced in isolating plastic material ideal for high temperature, it protects users from accidental contact. It reduces energy consumption and improves the application quality, keeping adhesive temperature constant.

GUN CASING

The casing is built in “Ergal”, an aluminium alloy that considerably improves the product’s resistance to mechanical stress. The hard oxide cover makes gun cleaning and maintenance quick and easy.

MODULE AMX-45 AO/AC

All guns are equipped with a new AMX-45 AO/AC series module that ensures precise and regulated glue application. This level of performance is possible only because of the special attention dedicated during the design and construction phases. The most important aspect of the AMX-45 AO/AC module is its innovative gasket system with the double interchangeable cartridge, which guarantees a perfect seal at high pressures and temperatures in addition to simple, inexpensive, and long-lasting maintenance. The module is activated by compressed air both in opening and closing. This functionality, together with the Zero-Cavity nozzle, increases the application’s speed and the removal of any tail or “angel hairs” making a clear cut-off (differently from modules with spring closure).

GLUE FILTER

This guarantees better distribution of the glue and prevents nozzles from clogging due to the presence of impurities in the glue. The filter is integrated into the casing, and is easily accessible and can be quickly replaced without disassembling the hose.

NOZZLES

The gun is supplied with stainless steel Zero-Cavity self-cleaning nozzles made of stainless steel, available with a minimum diameter of 0.25 mm to a maximum of 1.2 mm. Zero-Cavity is the term used for the cut-off that directly closes the nozzle hole, eliminating any possible impurities and guaranteeing the constant cleanliness of the nozzle. This guarantees that the system always works properly. The wide range of nozzles includes a number of configurations and special designs, based on the Customer’s needs. Preo nozzles stand apart from the competition due to their basic technical features, which can be summarized as follows. First: the nozzles are made of durable materials with the highest level of resistance to wear and tear. Second: their thermal conductivity is much greater than the traditional steel, with the advantage of quick heat transmission, at least 8 times higher than normal. Third: concerns the construction geometry, due the fact that multi-way nozzles ensure the same reliability as the traditional Zero Cavity nozzles.

PREO flexible high pressure thermo heated hoses convey liquids maintaining their properties unaltered, thanks to the internal constant temperature. They are available in different models: standard and special versions (high temperature, with external water proof braid and with external rigid protective jacket for movement, with external reduced diameter, with inner exchangeable glue tube and with air tube for spray). They are suitable for all different models of dosing systems present on the market and are used in all industrial fi elds requiring high quality, resistance and careful control of the temperature. They are available with different nominal diameters of the internal hose (6, 8, 10, 13, 16, 20 and 25 mm), with lengths that differ from 0,4 up to 12 meters and with working temperature between 50 and 230°C, in order to grant the same application precision, safety and reliability in controlling all different fl ows. The connection end fi ttings are available in a wide range allowing the perfect hydraulic connection between applicator and gun. Manufactured in galvanized steel, on Customer’s request they can be demanded made of other materials (brass, iron, stainless steel) and equipped with different threads (BSP, metric, J.I.C, ASA etc.), in order to fulfil any possible technical or production requirement.

POLYTETRAFLUOROETHYLENE (PTFE) INNER HOSE

Available in different diameters, it is obtained through the extrusion and sintering of Polytetrafl uoroethylene (PTFE). It resists also to particularly aggressive adhesives and to temperatures over 230°C (450°F).

STAINLESS STEEL BRAIDING

Built in stainless steel 18/8-AISI 304, it assures protection and resistance to the working pressures.

HEATING RESISTANCE

It brings the inner hose made of PTFE in temperature and wraps it around. It is of variable power.

TEMPERATURE SENSOR

It detects the material temperature allowing its continuous control.

GLASS FIBER TAPE

It maintains the temperature constant wrapping and protecting the resistance.

QUICK PLUG-IN CONNECTORS

They grant the electric connection between machine and gun. They can be supplied in different typologies and models.

INSULATING FOAM

It helps to keep the temperature to the level required thanks also to the silicon foam with which it is composed.

WIRE CONDUCTORS

Equipped with earth conductors, they supervise to the heating and control of the guns solenoid valve (24V).

PROTECTIVE EXTERNAL BRAIDING

It increases the mechanical resistance against heat, strokes, abrasions wear and handling. It is available in Polyamide or in water-repellent silicon.

END CAPS

The electrical connection takes place here. They can be rigid or made of silicon and thanks to their particular resistance, they protect the hoses ends.

TERMINAL FITTINGS

They are manufactured with different threads and materials in accordance with the specifi c requirement and allow the hydraulic connection between machine and gun granting a perfect tightness in all circumstances.