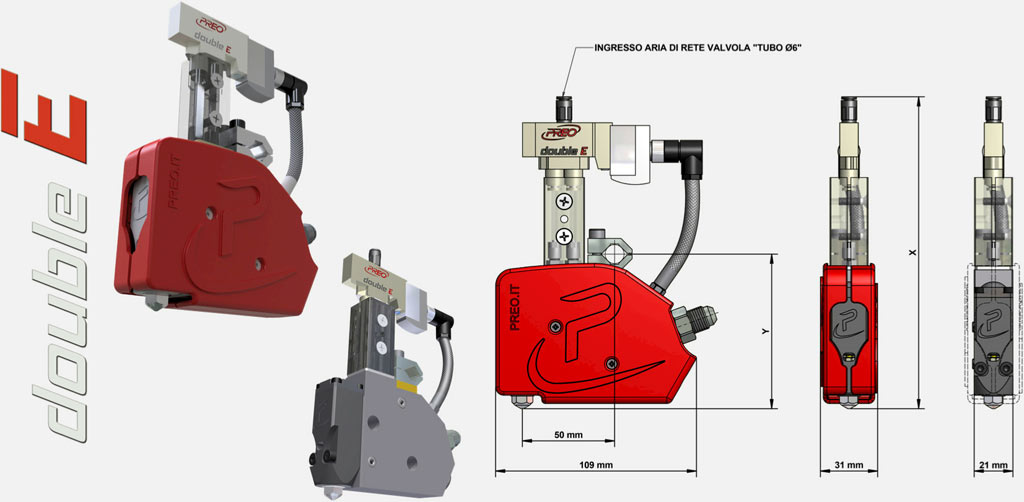

The new guns DOUBLE E series, with isolation cover integrated, are available in a wide and complete scale of models to permit the most demanding Costumer to find every time the most suitable solution to each gluing issue. Designed for the distribution of thermoplastic adhesive with high and medium viscosity, they are realized with one or more modules configuration, different center-distances and nozzles and with one or more solenoid valve. The main characteristics of DOUBLE E series are: compact design and reduced dimension perfect for installations in narrow spaces, modular elements, speed up to 8.000 cycles/minute, high reliability with a service life of more than 50 millions cycles, module double effect AMX-45 AOAC (with double interchangeable cartridge), Zero-Cavity self-cleaning nozzle, isolation cover in hard plastic and non-stick protective coating on gun’s case with integrated glue filter removable without disassembling the hose.

SOLENOID VALVES

A large choice of solenoid valves is available, both standard and special expressly developed for guns Double E. Depending on the required applications, these valves can deliver the highest level solution for tasks that require low energy consumption, high-speed application, small size and weight.

INSULATION COVER

Produced in isolating plastic material ideal for high temperature, it protects users from accidental contact. It reduces energy consumption and improves the application quality, keeping adhesive temperature constant.

GUN CASING

The casing is built in “Ergal”, an aluminium alloy that considerably improves the product’s resistance to mechanical stress. The hard oxide cover makes gun cleaning and maintenance quick and easy.

MODULE AMX-45 AO/AC

All guns are equipped with a new AMX-45 AO/AC series module that ensures precise and regulated glue application. This level of performance is possible only because of the special attention dedicated during the design and construction phases. The most important aspect of the AMX-45 AO/AC module is its innovative gasket system with the double interchangeable cartridge, which guarantees a perfect seal at high pressures and temperatures in addition to simple, inexpensive, and long-lasting maintenance. The module is activated by compressed air both in opening and closing. This functionality, together with the Zero-Cavity nozzle, increases the application’s speed and the removal of any tail or “angel hairs” making a clear cut-off (differently from modules with spring closure).

GLUE FILTER

This guarantees better distribution of the glue and prevents nozzles from clogging due to the presence of impurities in the glue. The filter is integrated into the casing, and is easily accessible and can be quickly replaced without disassembling the hose.

NOZZLES

The gun is supplied with stainless steel Zero-Cavity self-cleaning nozzles made of stainless steel, available with a minimum diameter of 0.25 mm to a maximum of 1.2 mm. Zero-Cavity is the term used for the cut-off that directly closes the nozzle hole, eliminating any possible impurities and guaranteeing the constant cleanliness of the nozzle. This guarantees that the system always works properly. The wide range of nozzles includes a number of configurations and special designs, based on the Customer’s needs. Preo nozzles stand apart from the competition due to their basic technical features, which can be summarized as follows. First: the nozzles are made of durable materials with the highest level of resistance to wear and tear. Second: their thermal conductivity is much greater than the traditional steel, with the advantage of quick heat transmission, at least 8 times higher than normal. Third: concerns the construction geometry, due the fact that multi-way nozzles ensure the same reliability as the traditional Zero Cavity nozzles.